Introduction

Thermal imaging surveys are becoming increasingly recognised as an effective methodology for enhancing health and safety in large commercial buildings. These surveys utilise specialised cameras that detect infrared radiation emitted from objects, allowing for the visualisation of temperature variations. This technology serves as a powerful tool for identifying potential safety hazards, ensuring compliance with health and safety regulations, and ultimately safeguarding both employees and assets.

The significance of health and safety in the context of large commercial buildings cannot be overstated. Such environments often encompass complex systems and a myriad of potential risks, necessitating rigorous safety protocols. By integrating thermal imaging surveys into routine safety assessments, building owners and managers can proactively mitigate risks, enhance operational efficiency, and foster a culture of safety. This article delves into the multifaceted benefits of thermal imaging surveys, their implementation, and real-world applications in improving health and safety standards.

The Role of Thermal Imaging in Enhancing Safety

Identifying Potential Hazards

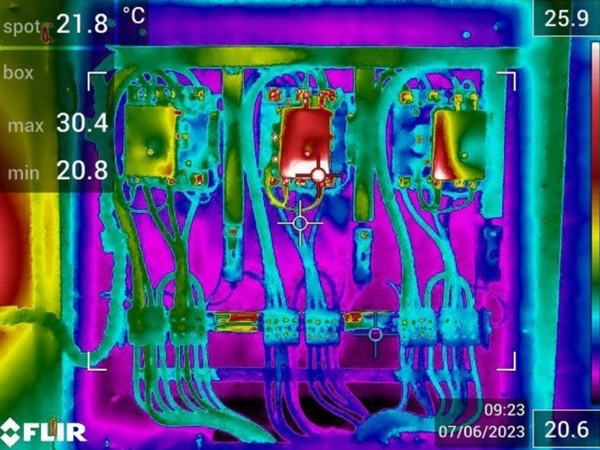

One of the primary advantages of thermal imaging surveys is their ability to identify potential hazards that may not be visible to the naked eye. This includes detecting overheating electrical components, identifying insulation deficiencies, and pinpointing moisture intrusion in wall assemblies. For instance, electrical connections that exhibit elevated temperatures are often the precursor to failures, potentially leading to fire hazards if left unchecked. Thermal imaging can swiftly highlight these issues, enabling timely interventions.

Moreover, thermal imaging can reveal problems within HVAC systems, such as blockages or system inefficiencies. By ensuring that heating and cooling systems are operating correctly, building managers can promote a comfortable environment for occupants while reducing energy consumption. This proactive approach to hazard identification aligns with the overarching goal of maintaining a safe working environment and underscores the critical role that thermal imaging plays in health and safety protocols.

Reducing the Chance of Falls from Height

Falls from height represent a significant risk in large commercial buildings, particularly in sectors such as construction, maintenance, and facility management. Thermal imaging surveys can be instrumental in assessing conditions that may contribute to slips and falls. For example, moisture buildup on surfaces, which can lead to slips, can be detected through temperature fluctuations that indicate water presence. By addressing these issues before they escalate into accidents, thermal imaging significantly enhances workplace safety.

In addition, thermal imaging can aid in evaluating the integrity of safety equipment such as ladders and scaffolds by identifying weaknesses or wear that may not be immediately apparent. By reinforcing safety measures through the insights gained from thermal imaging, businesses can create a safer environment.

Benefits of Thermal Imaging Surveys

Improved Health and Safety Standards

The implementation of thermal imaging surveys leads to improved health and safety standards across the board. By detecting underlying issues early, building operators can address hazards proactively rather than reactively. This shift towards preventative maintenance not only enhances safety but also aligns with industry best practices and regulatory requirements. Consistent thermal imaging surveys signify a commitment to health and safety, leading to increased trust and morale among employees.

Furthermore, the documentation provided by thermal imaging surveys strengthens compliance with health and safety regulations. In the event of an inspection, maintenance records, including thermal imaging assessments, can demonstrate due diligence and proactive risk management, significantly reducing the likelihood of penalties or safety citations.

Saving Money Through Preventative Measures

Investing in thermal imaging surveys ultimately translates into significant cost savings for businesses. By identifying potential failures before they occur, organizations can undertake preventative maintenance that is far less costly than emergency repairs. For example, the cost of replacing an overheated electrical component after a fire incident far exceeds the cost of conducting routine thermal imaging inspections to catch the issue early.

Moreover, improved energy efficiency resulting from identifying HVAC and insulation issues can lead to substantial reductions in utility bills. For large buildings, these savings can accumulate to significant figures over time. As such, thermal imaging surveys not only enhance safety but also provide a solid return on investment through preventative measures and efficiency improvements.

Save Time with Quick Reporting

Another key benefit of infrared surveys is the speed at which results can be obtained and reported. Unlike traditional inspections that may require extensive downtime or disruption of operations, thermal imaging can be conducted swiftly, often without interrupting the normal function of the building. The speed of diagnosis allows for immediate decision-making regarding safety and maintenance actions.

Additionally, the visual nature of thermal imaging allows for clearer communication of findings to stakeholders. Reports generated from thermal imaging surveys are typically accompanied by visuals that clearly depict issues, making it easier for engineers and business owners to understand and act upon recommendations. This efficiency in reporting ultimately contributes to a culture of safety and accountability.

Implementation of Thermal Imaging Surveys

How to Conduct a Thermal Imaging Survey

Conducting a thermal imaging survey involves several critical steps to ensure accuracy and effectiveness. First, it is essential to choose the right time for the survey, preferably when the building is at its normal operating conditions. This ensures that the thermal images reflect typical performance and reveal any anomalies accurately.

Next, the survey should be conducted by trained professionals who can interpret the thermal data appropriately. They will use specialised professional infrared cameras to scan areas of concern, such as electrical panels, HVAC systems, and insulation. Once the imaging is complete, the data is analyzed, and a comprehensive report is generated outlining any identified issues along with recommendations for corrective actions.

Choosing a professional Thermal Imaging Provider

Selecting an experienced service provider for thermal imaging surveys is crucial to the success of the implementation. Professionals should have relevant certifications and training in both thermography and the specific health and safety requirements applicable to commercial buildings. It’s beneficial to check references and review case studies that demonstrate the provider’s expertise and successful track record.

Moreover, the thermal imaging company should employ advanced equipment and technologies to ensure the highest quality results. A thorough understanding of the building’s systems, along with the ability to communicate findings effectively to stakeholders, is essential for driving meaningful change in health and safety practices.

Case Studies and Success Stories

Examples of Improved Safety in Large Commercial Buildings

Many organizations have seen tangible improvements in safety standards as a result of implementing thermal imaging surveys. For instance, a large manufacturing facility that integrated regular thermal surveys discovered multiple overheating electrical panels that could have led to significant fire risks. After addressing the identified issues, the facility not only reduced the likelihood of accidents but also received insurance discounts due to improved safety measures.

Another case involved a corporate office building that was experiencing inconsistent heating and cooling. By deploying thermal imaging, the facility managers identified several areas with insufficient insulation and malfunctioning HVAC components. Rectifying these issues not only enhanced occupant comfort but also resulted in a drastic reduction in energy costs.

Feedback from Engineers and Business Owners

Feedback from engineers and business owners who have utilised thermal imaging surveys underscores its effectiveness. Engineers report increased confidence in their ability to identify and address issues before they escalate into serious problems. Business owners express satisfaction with both the safety improvements and the savings achieved through enhanced operational efficiency.

Conclusion

Summary of Key Points

Thermal imaging surveys offer significant benefits for enhancing health and safety in large commercial buildings. By identifying potential hazards, reducing the chance of falls from height, and improving overall health and safety standards, these surveys provide a proactive approach to risk management. The financial savings gained from preventative measures and energy efficiencies further underscore the value of adopting this technology.

Implementing thermal imaging surveys involves careful planning, execution, and the selection of qualified service providers. Real-world case studies illustrate the tangible improvements in safety and operational efficiency that can be achieved, supported by positive feedback from industry professionals. As the conversation surrounding workplace safety continues to evolve, thermal imaging will undoubtedly remain an essential element in the quest for safer commercial environments.

Frequently Asked Questions

What is a thermal imaging survey? A thermal imaging survey uses infrared cameras to detect temperature variations in surfaces, helping to identify potential hazards such as overheating electrical components or insulation failures.

How often should thermal imaging surveys be conducted? The frequency of thermal imaging surveys depends on several factors, including the age of the building, the complexity of its systems, and industry requirements. Regular intervals, such as annually or biannually, are often recommended.

What are the costs associated with thermal imaging surveys? Costs can vary depending on the size of the building, the complexity of the systems being inspected, and the service provider. However, the potential savings from preventing major issues often outweigh the initial investment.

Are thermal imaging surveys compliant with health and safety regulations? Yes, thermal imaging surveys are widely recognised as an effective means of ensuring compliance with health and safety regulations, demonstrating proactive risk management and maintenance practices.

Can thermal imaging surveys help with energy efficiency? Yes, thermal imaging surveys can identify insulation deficiencies and HVAC inefficiencies, leading to corrective actions that result in significant energy savings and enhanced operational efficiency.

Our Premium Thermal Imaging Service

- Supply of an ITC trained Level 3 thermographer

- We us large format FLIR P6n-Series (640×480 resolution) thermal imaging cameras.

- Comprehensive report to include Introduction and fault cover pages, summary problem pages, elevation inventory,

- Detailed fault documentation pages with possible root cause and remedial recommendation (isotherm included if using equations), baseline IR and DC image of every elevation (100% coverage-no isotherm)

- Application of thermal indexing formulas

- Eco Friendly Email Report

Please contact us for more information If you would like to contact us for more information on our thermal imaging services, please contact us on 07775623464, or email us at info@aptsoundtesting.co.uk.