So, how do thermal imaging surveys help diagnose issues in buildings? A thermal image contains thousands of surface temperature measurements, this makes it easy to see where insulation is missing, or air is leaking through the building fabric. When combined with blower door testing, thermal imaging inspections becomes an incredibly powerful tool. its also one of the quickest and low impact methods to identify defects within the building fabric, i.e. walls, floor, roof, windows and doors.

Visible light forms only a small part of the electromagnetic spectrum, and the only part that humans see. When pointed at an object or area such as a wall, the sensor on a thermal detection camera allows the user to view the otherwise invisible infrared spectrum, which exists at wavelengths between visible light and microwaves. The resulting thermal image is usually rendered as a colour map, with the warmer components or regions shown as reds, oranges, and yellows, while cooler parts will typically be shown as purples and blues – green usually indicates areas that are roughly at room temperature. We usually use high resolution Flir cameras for our BREEAM thermal Imaging Surveys.

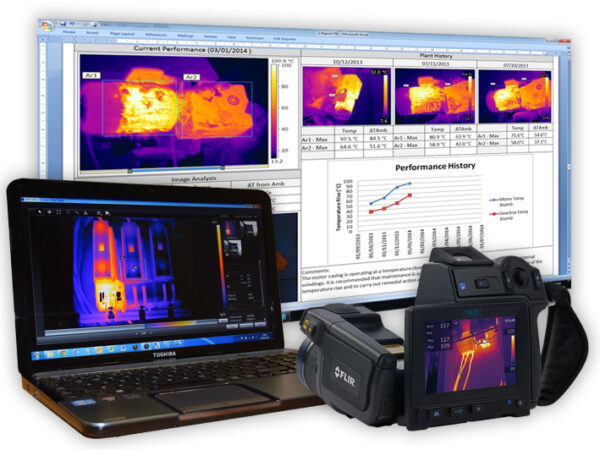

Always use high quality thermal imaging cameras

Our high quality thermal imaging cameras have a minimum resolution of 640 x 480 and also include a standard shooting mode that works with the visible light spectrum, much like a standard point and shoot digital camera. This allows for easy comparison of two identical shots, the first image in Infrared and the second image in normal photographic mode, this quickly helps to identify specific problem areas once the our thermography engineer steps out from behind the lens and compares images. In all cases the higher resolution the thermal camera retains, the more detail that can be captured and scrutinised as part of our reportage.

Any surveyed objects not generating or absorbing heat will tend towards the surrounding air temperature, so cold air leaking through the building envelope will show as cold patches on the wall, floor or ceilings. Warm air leaking from a building envelope will cause warm patches on the outside wall or roof. Thermal imaging surveys alone can be used as a quick method of finding air leaks in a building structure, however the accuracy can be further improved if used in conjunction with an air tightness test which can better quantify the air leakage of a building. in most cases a combined thermal and air tightness test is the best option for fault diagnoses in building envelopes.

We can help with your Thermal Imaging Survey

Our team of APT thermographers are highly experienced and trained to Level 3 for carrying out thermal imaging surveys and have many years’ experience in all aspects of engineering, construction, maintenance, management, and professional survey work and all our thermographic surveys are conducted by engineers qualified in accordance with BS EN 13187

Our thermal imaging equipment is the best and most accurate on the market, ensuring we pick up faults that other equipment may miss. Our reports are professionally presented and are clear, concise, and easy to follow. We endeavour to give our clients a first class service every time.

If you would like to contact us for more information on our air tightness and thermal imaging services, please contact us on 01525 303905 or email us at info@aptsoundtesting.co.uk.