Air tightness testing contains lots of confusing terminology, to try and help our clients navigate through the main keywords we have written the following Air Tightness A to Z article on air tightness testing.

Air Tightness Testing Terminology

- A is for Air leakage paths – the uncontrolled movement of air into and out of a building via air leakage paths within the building envelope.

- B is for Blower door test equipment – the device that is installed into an external opening such as a doorway to pressurise or depressurise the building and measure the air leakage rate. Blower door fan systems can be modular so they can be combined to test very large buildings. Retrotec is one of the largest manufactures of blower door equipment.

- C is for Cubic metres per hour per square metre of envelope area – the unit of measurement for air leakage rate in the UK Building Regulations and to the ATTMA standards.

- D is for Drafts through the building envelope – the uncomfortable air currents that can occur in a building with poor air tightness.

- E is for Envelope – the term used to describe the external floors, walls roofs, doors and windows of a building that separate the inside from the outside atmospheres.

- F is for Fabric first approach – a strategy of designing and constructing a building with high levels of insulation and air tightness to reduce the reliance on space cooling and heating and mechanical ventilation.

- G is for Gaps and cracks – the unauthorised openings in the building envelope/fabric that allow air to leak in or out, such as around service penetrations, windows, doors, eaves junctions etc.

- H is for Heat recovery system – a system that provides fresh air to a building while recovering the heat from the exhaust air and transferring it to the incoming air. Buildings need to have high levels of air tightness for this system to work.

- I is for Insulation – high levels of insulation reduces the heat transfer between the inside and outside of a building. Combined with good air tightness it works well in reducing heat loss through air leakage.

- J is for Joints – the connections between different elements of the building envelope, such as wall/ceiling junctions, wall panels, roof tiles, floorboards, etc. Poorly sealed joints can be one of the major causes of air leakage in new buildings.

- K is for K-Value – this is simply shorthand for thermal conductivity. This is a measure of the thermal conductivity of a material, that is, how easily heat passes across it.

- L is for Litre per second per square metre of floor area – another unit of measurement for air leakage rate that is sometimes used in some countries. It is equivalent to 3.6 times the cubic metre per hour per square metre of envelope area unit.

- M is for Mechanical ventilation – a system that uses fans or pumps to supply or extract air from a building. Mechanical ventilation can be balanced, meaning that the supply and extract rates are equal, or unbalanced, meaning that there is either more supply or more extract than the other which is often used in laboratory/cleanroom environments.

- N is for Natural ventilation – a system that relies on natural forces such as external air movement such as wind to provide fresh air to a building. Natural ventilation can be passive, using devices such as trickle vents, air bricks, louvres, or windows to control airflow through the building fabric.

- O is for Occupants – the people who live or work in a building. Occupants can have a significant impact on the air tightness of a building by opening or closing windows and doors. This can be difficult to control as most individuals have their own favoured working environment, i.e., some like high levels of ventilation and cooler working conditions than others.

- P is for Pascals – the unit of pressure that is used to measure the difference between the indoor and outdoor air pressure during an air tightness test. A Pascal is equal to one Newton per square metre. The standard pressure difference used for air testing is 50 Pascals, with testing between 25 to 70 Pascals in 5 Pa increments.

- Q is for Quality assurance – the process of ensuring that the building design and construction meets the required standards and specifications for the building regulations and employers’ requirements. This involves checking drawings, inspecting materials, monitoring workmanship and the final signoff process.

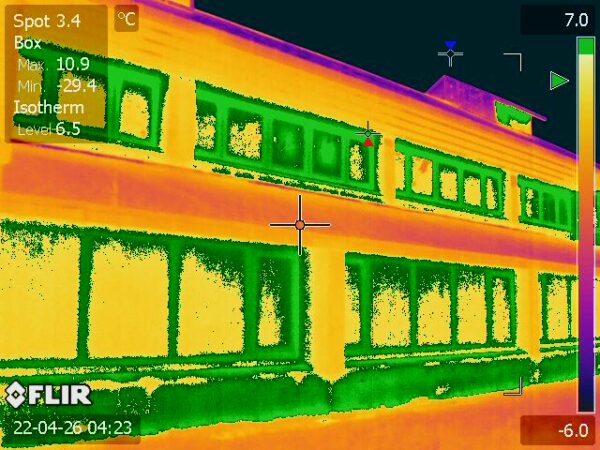

- R is for Retrofitting buildings – the process of improving the energy efficiency of an existing building by upgrading various elements such as windows, doors, insulation, ventilation systems, etc. Implementing air tightness upgrades to the building envelope can also involve improving the air tightness of a building by sealing gaps and cracks in the envelope during the retrofitting process. Identifying air leakage paths can be done via combined blower door, smoke testing and thermal imaging air leakage surveys.

- S is for Smoke leakage test – a method of visually identifying sources of air leakage in a building envelope by using smoke generating devices such as large and small smoke machines. When aligned with blower door and thermal imaging, Smoke tests can be useful during construction or retrofitting to locate and seal leaks should the building fail the air tightness test.

- T is for Thermal imaging – a method of visually identifying sources of heat loss in a building by using a thermal imaging camera that detects infrared radiation and displays it as a coloured image. Thermal imaging extremely useful to locate air leakage paths when used with a blower door useful during the construction or retrofitting of buildings.

- U is for U-value – the measure of how much heat is transferred through a unit area of a material or a building element with the building fabric. The lower the U-value, the better the thermal performance. U-values are affected by the thickness, density, conductivity, and air tightness of the building element.

- V is for Ventilation rate – the measure of how much air is supplied or extracted from a building per unit time. Ventilation rate can be expressed as air changes per hour, litres per second or cubic metres per hour. The ventilation rate is influenced by the type and size of ventilation system, the building air tightness, indoor and outdoor air pressure, temperature and humidity, and the occupant’s behavior.

- W is for Weather conditions – the factors that affect the outdoor environment such as temperature, humidity, wind speed and direction, precipitation, etc. Adverse weather conditions such as high winds, can have an impact on the air tightness of a building by creating pressure differences between the inside and outside, as well as affecting the thermal performance and comfort of the building.

- X is for X-factor – a term used to describe the unknown or unpredictable factors that can affect the air tightness of a building. Examples of X-factors include adverse weather conditions, human error, faulty equipment and unexpected events. X-factors can cause variations or discrepancies in the air tightness test results or performance of the building.

- Y is for Yearly savings – this is the amount of money that can be saved by improving the air tightness of a building. Yearly savings can be calculated by estimating the reduction in energy consumption and carbon emissions due to lower heat loss and lower ventilation demand which can be as much as 30%. Yearly savings can also include other benefits such as improved comfort, health, and productivity.

- Z is for Zero carbon – a term used to describe a building such as Passive house, that has no net emissions of carbon dioxide or other greenhouse gases over its life cycle. Zero carbon buildings can be achieved by combining high levels of insulation and air tightness with renewable energy sources and low carbon materials to achieve their Zero Carbon status.

We can help with your Air Tightness Testing

If you have any questions in regards to the air tightness testing on your building project, please don’t hesitate to call Darren on 07775623464. We have qualified and experienced professionals who can provide you with high-quality testing service and advice.

Alternatively, please email us at: info@aptsoundtesting.co.uk, or visit our website at www.aptsoundtesting.co.uk