The consequences of not testing smoke shafts, can have serious repercussions for building and occupant safety.

Here are just a few of the potential consequences:

- Ineffective/Poor Smoke Extraction – Without regular air tightness testing, smoke shafts may become compromised due to wear, damage, or poor maintenance. In the event of a fire, ineffective smoke extraction can lead to reduced visibility, hindering evacuation efforts and endangering lives.

- Non-Compliance with Regulations – Many building regulations mandate smoke shaft testing. Failure to comply can result in legal penalties, fines, or even closure of the building. Non-compliance also undermines the safety of occupants and emergency responders.

- Insurance Implications – Insurance policies often require compliance with safety standards. If smoke shafts are not tested, insurance claims related to fire damage may be denied.

- Increased Fire Spread Risk – Smoke shafts play a critical role in containing smoke within designated areas. If smoke shaft fail, smoke can spread rapidly, throughout the building affecting adjacent floors and compromising escape routes. Increased smoke propagation can exacerbate fire damage and endanger lives.

- Health Hazards – Smoke inhalation is a significant health risk during fires. Inadequate smoke extraction due to untested shafts can expose occupants to toxic fumes, leading to respiratory issues or fatalities.

- Emergency Response Challenges – Firefighters rely on functioning smoke shafts to manage smoke and heat during firefighting operations. Non-operational shafts can hinder their efforts, jeopardizing both occupants and responders.

In summary, regular (annual) smoke shaft testing is essential for maintaining building safety, complying with regulations, and safeguarding lives during emergencies.

What is the accompanying legislation for air testing smoke shafts

- The Approved Document B – this provides guidance on fire safety and mentions the role of AOV systems in facilitating evacuation by clearing smoke. It’s important to refer to the latest version of this document for detailed guidelines.

- BS EN 12101-2:2006 – AOV smoke shafts must comply with standards such as BS EN 12101-2:2006, which covers the design of smoke ventilation systems.

- BS EN 9991 (2015) – Fire Safety in the design management and use of residential buildings.

Further smoke shaft testing guidance is available in the Colt Smoke Control in Apartments Leaflet, available as a free download from www.coltinfo.co.uk. SCA “Guidance on smoke control to common escape routes in apartment buildings”, is also available as a free download from www.FETA.co.uk

Our roadmap to passing a smoke shaft air test

On previous projects we have used the following road map to help client pass their smoke shaft air test:

- Smoke shaft survey visits to check the shaft has been built correctly

- Envelope calculations undertaken by ATTMA calculation experts

- Smoke testing in the event of an air test failure

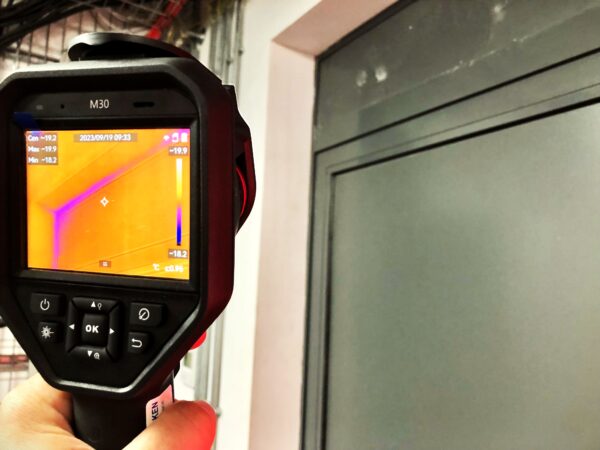

- Thermal Imaging in the event of an air test failure

- Clear and concise air leakage reports

- Final smoke shaft air test certification by UKAS & ATTMA Level 2 testing company

We help clients pass their smoke shaft air testing

There are many reasons why you should choose us to undertake the air testing to your smoke shafts, here are just a few of them.

- We are a UKAS accredited air testing company

- We are a ATTMA Level 2 accredited

- Our company is accredited to undertake envelope calculations.

- We have undertaken smoke shaft tests to hundreds of smoke shafts to CIBSE TM23

We can provide next-day smoke shaft certificates and offer our best price guarantee. We can help you every step of the way from the initial site survey visit through to the final testing. Generally, our clients find that involving us as early as possible saves them the most money. Our expert advice helps them avoid expensive remedial work, ensuring all their smoke shafts pass first time.

Please get in touch to discuss your next smoke shaft air pressure testing requirements.

For more information please contact Darren direct on 07775623464 or email us at info@airpressuretesting.net

If you would like more information on our smoke shaft air testing services, please contact Darren direct on 07775623464 or email us at info@airpressutestesting.net