Many clients ask why they need to undertake air testing to their smoke shafts, so let us explain the why’s and how in more detail. All building that have a smoke shaft, should have an air tightness test in compliance with Legislation and standards, such as BS 9999 and BS 9991. Air testing for smoke shafts is a critical step in ensuring safety and compliance. Let’s explore why it’s essential:

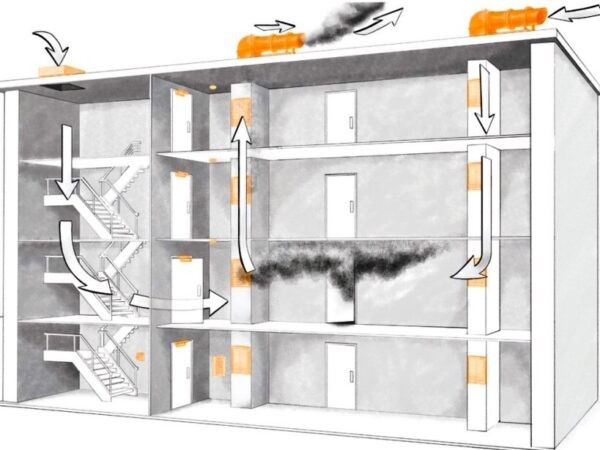

- Smoke Control and Fire Safety: In the event of a fire, smoke is a significant contributor to deaths and injuries, often surpassing the impact of the fire itself

- More than 60% of deaths occur due to smoke inhalation, emphasizing the importance of controlling smoke

- Smoke control systems protect escape routes and assist firefighters, reducing fatalities and injuries.

Smoke Shaft Functionality:

- Smoke shafts play a crucial role in evacuating smoke from buildings during a fire

- To function effectively, smoke shafts must be airtightto allow mechanical Automatic Opening Ventilation (AOV) systems to extract smoke from escape/access routes

- Air testing confirms the shaft’s airtightness before AOV commissioning to allow the smoke shaft to be signed off by the builder.

Building Regulations and Standards for Smoke Shafts

AOV Smoke shafts are subject to an ever-evolving network of standards and legislation in the UK. For residential buildings, BS 9991:2015 provides updated fire safety guidance, including recommendations for smoke control.

Air Testing Process for Smoke Shafts:

Air tightness testing of smoke shafts involves a positive pressurisation test using a high-powered blower door fan. The test occurs when the shaft is fully sealed but before AOV fans and louvres/shutters are installed.

If the shaft fails to achieve the airtightness target, a smoke leakage test is conducted. During the smoke test, theatrical smoke is pushed into the shaft, revealing any gaps or cracks in the smoke shaft envelope. on large smoke shafts over multiple floors, its best that multiple observers are used to check the floors whilst the air test engineer operates the blower fan equipment.

In summary, air testing ensures smoke shafts meet safety standards, protect lives, and enhance fire safety.

We can help you pass your smoke shaft air test

We have been undertaking AOV smoke shaft testing throughout London and the South-East, on many prestigious projects such as Battersea Power Station, The Imperial War Museum and Clarridges and Berkeley Hotel.

Our experienced engineers at Air Pressure Testing have over 10 years in the field of smoke shaft testing, so we know how to help clients to pass their testing and achieve smoke shaft signoff.

What can we do?

- Smoke shaft survey visits

- A UKAS and ATTMA Level 2 testing company

- Smoke shaft air test certification

- The latest high-powered fan equipment

- UKAS calibrated equipment

- Smoke testing in the event of an air test failure

- Thermal Imaging in the event of an air test failure

- Same day quotation

- Experienced test engineers

- Thousands of air pressure tests undertaken

- Fantastic customer satisfaction score

Air Pressure Testing Ltd boasts a client base from one of self-builders to the largest construction companies in the UK. We offering leading design, consultancy and compliance for every part of your project, at all stages. It’s APT’s aim to provide a friendly and professional stress-free experience.