Electrical thermal Imaging inspections, makes it possible to identify electrical defects such as loose connections and over loaded circuits (one of the most common causes of electrical fires in buildings) faults to transformer cooling systems to name but a few. we ofetn get asked what type of electrical equipment require thermal imaging inspections? An infrared survey inspects electrical equipment installations throughout the buildings, whilst the equipment is in operation, causing no disruption to business operations. We have undertaken hundreds of thermal imaging surveys to electrical systems throughout London and the South East by our Level 3 trained thermographers, so you can be sure you are in safe hands.

Electrical thermographic inspections can be undertaken to literally dozens of different types of electrical systems and plant; however, here is a list of the most common electrical equipment that usually require thermal imaging inspections, they are as follows:

- Switchgears and switchboards

- Distribution boards and fuse boards

- Transformers

- Control panels

- Busbar systems

- High voltage systems

- Batteries

- UPS systems

- Heating and ventilation panels

- Motor and pumps

- Generators

Will I find many electrical issues within my building?

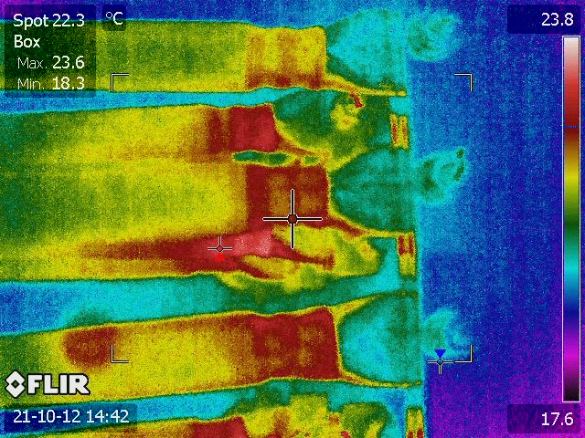

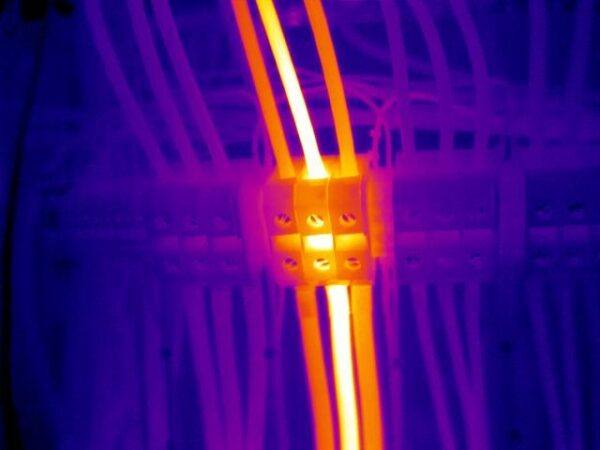

Historically, we usually find defects during each visit. This can be loose or corroded contacts, load imbalances, poor cable joints or an overloaded transformer – all of which will generate excess heat and previous data from thermal imaging of electrical installations shows a significant rate of potential fault detection for an initial survey, typically in the region of one to two faults for every 10 panels inspected – if you have 50 panels that may result in 10 faults!

A thermal camera can often show the problem before an electrical test or visual inspection would uncover it. The severity of the problem can be determined by comparing the temperature rise of the fault with the properly operating component under the same loading conditions.

Past data from thermal imaging of electrical installations shows a significant rate of potential fault detection for an initial survey, typically in the region of one to two faults for every 10 panels inspected.

Contact us now for more information on our infrared electrical surveys

If you require a electrical thermal imaging inspection our professional and certified Level 3 Thermographer’s will carry out your thermographic Inspections for all necessary standards and current regulations.

All we need are a few details such as the building address and the number of electrical installations within the building. Floor plans and would also be helpful to allow us to orientate ourselves during the inspection. We will also send across our informative checklist to help you prepare for the thermal survey.

If you would like to contact us for more information on our thermal imaging services, please contact us on 01525 303905 or email us at info@aptsoundtesting.co.uk Please call 01543 225306 or fill out one of our contact forms to discuss our service levels and to run a thermographic inspection for your business. Talk to us today so we can keep you and your business safe.