Thermal imaging is an incredibly powerful tool for identifying air leakage on smoke shafts that have failed the air tightness test. Here is the survey methodology on how thermal imaging can help identify air leakage paths within the smoke shaft envelope to allow the contractor to undertake targeted remedial sealing works.

Advantages of thermal imaging smoke shafts

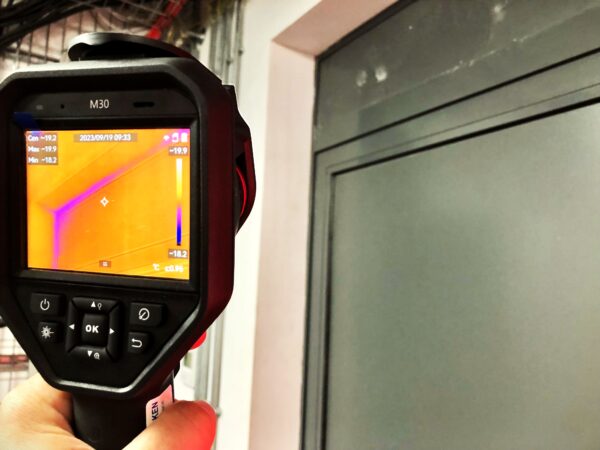

Thermal imaging reveals the pathways that cold/warm air follows, making it easier to identify air leakage paths within the envelope of the smoke shaft. It is also less disruptive than smoke surveys as it doesn’t impact visibility for operates and/or lead to possible callouts from the emergency services.

Method: To undertake accurate thermal imaging the test area needs to be pressurised whilst the shaft is being heated with small electric blow heaters. For health and safety reasons the blow heaters are set up on the landings on the lower and mid floor, and the ductwork run into the shafts via the AOV openings. A high resolution calibrated thermal imaging camera is then used to locate areas where hot air is escaping through the envelope of the smoke shaft. The advantage of thermal imaging is that it clearly shows the pathway the hot air is following which can them be recorded with the thermal camera and the finding sent to the contractor so they can undertake targeted remedial sealing works. Also, it negates the need for smoke testing which can be more disruptive to building projects.

Thermal imaging can also be used in conjunction with the smoke leakage method. It can highlight the path of the smoke as it travels through the wall to the outside.

Combining Thermal Imaging and Blower Door Testing:

Procedure:

- Shut all AOV doors, except where you will be setting up the equipment inline with our smoke shaft checklist.

- Set up small blow heaters, with the associated ductwork terminating into the smoke shaft.

- Set up a blower door system to pressurise or depressurise the entire smoke shaft.

- We use a high resolution thermal imaging camera to capture images of the smoke shaft envelope.

- Produce a detailed thermal imaging report highlighting the air leakage paths through the fabric of the smoke shaft envelope.

Benefits: Remember that thermal imaging provides a visual representation of heat loss and air leakage, helping your client to target the remedial sealing works more effectively.

Why use APT for your smoke shaft air testing?

You can use any ATTMA level 2 company to test your smoke shaft; however, what happens in the event of air test failure?

If the smoke shaft fails the air test, most companies simply pack up their equipment and leave the site. Not APT, we pride ourselves on offering one of the most comprehensive air leakage diagnostic services in the UK. Using our experienced test engineers, along with the latest air leakage equipment we can help you pass the air testing to your smoke shaft and achieve smoke shaft signoff.

here how we help in the event of a air test failure we provide the following services:

- Smoke testing with small/large mechanical smoke testers

- Thermal Imaging with high resolution cameras

- Clear and detailed smoke leakage survey reports

- Experienced test engineers that highlight the main air leakage paths whilst on site

Air Pressure Testing Ltd boasts a client base from one of self-builders to the largest construction companies in the UK. We offering leading design, consultancy and compliance for every part of your project, at all stages. It’s APT’s aim to provide a friendly and professional stress-free experience.

Further guidance is available in the Colt Smoke Control in Apartments Leaflet, available as a free download from www.coltinfo.co.uk. SCA “Guidance on smoke control to common escape routes in apartment buildings”, is also available as a free download from www.FETA.co.uk

Also, we are one of a few companies that is both UKAS and ATTMA Level 2 accredited for undertaking air tightness testing to buildings, as well as specialising in smoke shaft air testing. If you would like more information on our smoke shaft (AOV) testing and/or you would like to download our smoke shaft checklist, please contact Darren on 07775623464 or email us at: www.aptsoundtesting.co.uk