Noise Flanking Paths

To reduce the chance of sound testing failure, it is imperative that flanking transmission is considered at the design stage to reduce potential noise flanking paths. Good detailing at the design stage will minimise this effect and optimise the overall levels of acoustic privacy achieved. If designing for residential units, design advice on flanking details must be followed to maximise the possibility of achieving the specified acoustic performance. It is imperative that the design advice is followed, otherwise the site sound insulation values may not meet the performance criteria required and subsequent expensive remedial treatment may be required.

Flanking sound is defined as sound from a source room that is not transmitted via the separating building element e.g. the wall or floor partition. The sound is transmitted indirectly via paths such as external walls, windows, doors and internal corridors. One of the easiest ways of dealing with sound flanking issues is to use isolation strips around the perimeter of the partitions at the edges of floors and walls, this should be finished with acoustic sealant

One of the main reasons for flanking sound test failures is when the inner leaf of the perimeter wall is built with light weight blocks. This acts like a large snare drum and the sound simple travels straight up the wall from one flat to the flat above and/or below. Even if you have used a acoustically robust wall and/or floor partition the sound insulation testing may still fail. If you have used lightweight blocks in your onsite construction and the building fails the sound test you may need to construction independent internal plasterboard lining throughout the inner perimeter wall, this should isolate the lightweight blocks and ensure the flanking path is minimized.

If the onsite construction has gaps, cracks or holes it will conduct airborne sounds and can significantly reduce the sound insulation of a construction. For optimum sound insulation a construction must be airtight. Most small gaps can be sealed at the finishing stage using Gyproc jointing compounds. Small gaps or air paths around perimeter Gypframe framework can be sealed with sealant. At the base of the partition, gaps will occur which can be filled with acoustic mastic.

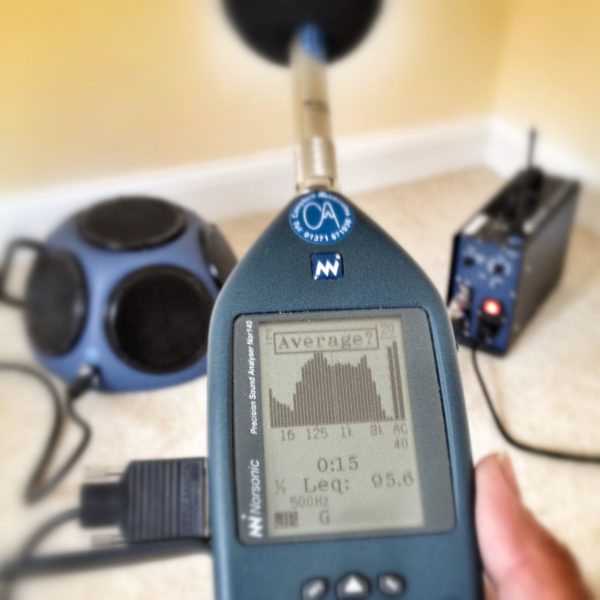

We operate a UKAS-accredited sound insulation testing service throughout London and the South East, providing customers reports to achieve building control sign off with a quick and reliable turnaround. We offer cost effective ‘one stop solution’ for all your sound testing requirements. We also offer large cost savings for developers requiring multiple services such as Air Tightness, Sound Insulation and Ventilation Testing throughout London and the South East.

As a UKAS accredited sound testing company, you can be sure our sound test reportage and acoustic design reports are of the highest standard, and will be accepted by your local London Building Control body. We provide highly competitive pricing and a friendly proactive service from the design stage of projects through to building completion and handover.

If you would like more information in regards to sound testing service and/or acoustic design services, please contact us on 01525 303905 or info@aptsoundtesting.co.uk. If you would like more information in regards to sound insulation testing and or acoustic design advice, then please call us now at info@airpressuretesting.net or call me (Darren) direct on 07775623464.