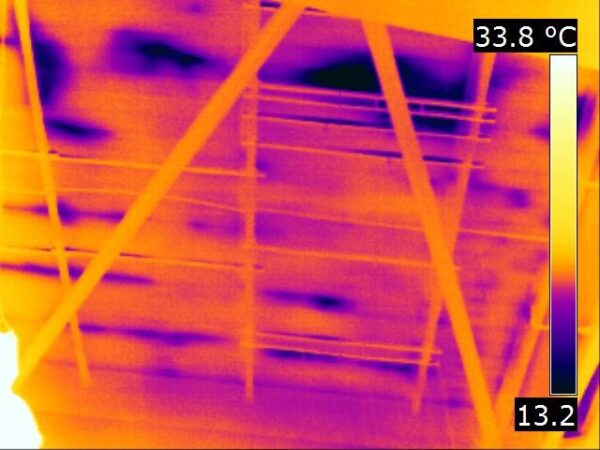

There are dozens of reasons a thermal imaging survey can be useful to you. One of the most common reasons for a thermal survey is to assess the energy efficiency of your commercial building and/or dwelling. More than ever, building owners are conscious of their energy usage and how much they are spending on heating their building and a thermal imaging survey can be a major factor in reducing that. Differences in temperature around the building envelope (thermal bridging) will show if the building is poorly or well insulated. On average our thermal imaging surveys will detect at least three areas of substandard insulation, potentially saving a customer thousands of pounds annually on their energy bills.

What Defect will thermal imaging identify

Our thermographic reports will detail the quality and amount of insulation in your building fabric construction, as well as highlighting the quality of the seals on external doors and windows and other areas that can allow heat to escape and ensure your central heating systems are working as efficiently as possible. Thermal Imaging surveys can also detect other building defects, such as missing or damaged insulation, roof leaks and of moisture/damp build.

We find many buildings also suffer from excess air leakage, by using our combined blower door & thermal imaging service we can highlight the air leakage paths, so targeted remedial sealing works can be carried out. With larger buildings savings of tens of thousands of pounds per year can be saved if the building if lowered from an air leakage rate of 15m3/hr/m2 down to 5m3/hr/m2. A thermal imaging survey gives you a clear conscience that you’re doing your bit to use as little energy as possible to improve your buildings green credentials.

We can help with your Thermal Imaging Survey

If you’re moving into a new building and you have concerns about the condition of the building envelope, a thermal imaging survey can detect hidden leaks, damp, as well as finding problems with electrical systems. Finding building defects early is key, allowing them to be treated and rectified with as little impact, disruption and cost as possible.

Please be aware of our high specification utilised in these inspections which surpasses those required by BREEAM, our Air tightness testers are UKAS and ATTMA accredited, and our thermographers are Level 3 certified, which is the highest accreditation available and all out surveys are carried out to BS EN 13187:1999

For more information on our thermal imaging services, please contact Darren on 07775623464, or contact us on info@aptsoundtesting.co.uk