What is a Thermographic Building Inspection?

Thermographic building inspection refers to the non-destructive testing of parts, materials or systems through the imaging of the thermal patterns at the object’s surface. Infrared thermography is a non-destructive, non-intrusive, noncontact mapping of thermal patterns or “thermograms”, on the surface of objects through the use of some kind of infrared detector.

We usually undertake active thermography, in which an an energy source is required to produce a thermal contrast between the feature of interest and the background, for example: a completed building with internal flaws such as missing insulation.

When compared with other classical non-destructive testing techniques such as radiographic testing and/or ultrasonic testing, thermographic inspections are nonintrusive and noncontact, allowing the detection of relatively shallow subsurface defects although thermal inspections of larger surfaces is possible.

Thermography is a type of photography which is based on infrared wavelengths (as opposed to visible wavelengths). Conventional photography relies on reflected energy from a light source, whether it’s artificial lighting or the sun, which is visible to our eyes. Thermal imaging relies on radiated energy in the infrared (IR) spectrum which cannot be seen by our eyes. All objects emit radiation energy within the IR spectrum and this IR radiation can and does vary depending on the temperature of that object.

Infrared Thermography Surveys on Building Envelopes are incredibly useful as it provides the most rapid means to identify unintentional air leakage pathways in a building envelope.

The benefits of infrared thermography in this context are:

-

-

-

-

-

- Air leakage pathways within a completed construction can be identified and rectified prior to air permeability tests, reducing the risk of repeat testing being required.

- Depending upon the nature of the construction, even a building that meets or exceeds air tightness requirements may still be at risk of deterioration due to air leakage and subsequent condensation. Identifying where air leakage is occurring can be critical.

- Air leakage pathways can often indicate rainwater ingress pathways adding to the potential benefits of an infrared survey.

-

-

-

-

Why pick APT Sound Testing to undertake your thermal survey?

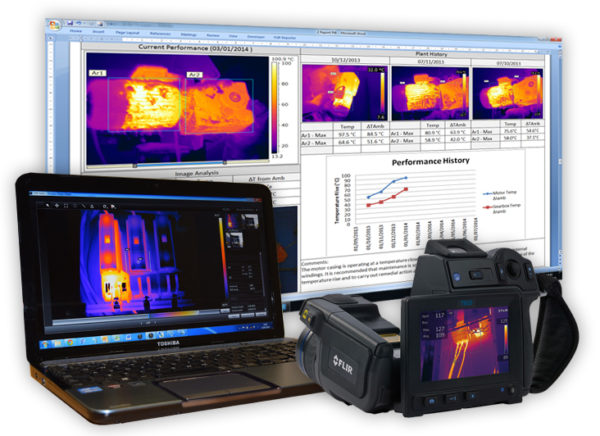

Please note that APT’s thermography engineers are trained to level 3, which is the highest level you can achieve as a thermographic engineer. We also use large format thermal imaging cameras; this provides you with the absolute best chance of solving any potential issues by utilising thermographic technology.

The importance of using one of our Level 3 trained thermographers cannot be understated as they are trained to be write predictive maintenance and inspection practices and to develop test procedures and ascertain severity criteria. To try and help clients prepare for the thermal imaging survey to their building, we have written the following article: How we carry our thermal Surveys on commercial buildings. Also, to help clients prepare for please find the link to our Thermal Imaging Checklist.

If you would like more information in regards to BREEAM Thermography Surveys in London, please contact us now at: info@aptthermography.net or call us direct at: 07775 623464