How we undertake a Room Integrity Test

Clients are understandably nervous prior to the undertaking of an integrity test on their server room/data centre, as its often their most important critical asset. To help explain this in more detail – and alleviate potential fears) we have collated the step by step guide for room integrity testing below.

- The enclosure is measured, a plan made and the type and quantity of extinguishant recorded. The height of the highest hazard in the enclosure (risk height) is noted.

- Where relevant, doors within the enclosure are opened and a number of false floor and ceiling tiles are removed so that the protected enclosure is tested as one space. A return air path is established outside the enclosure by opening doors/windows as appropriate.

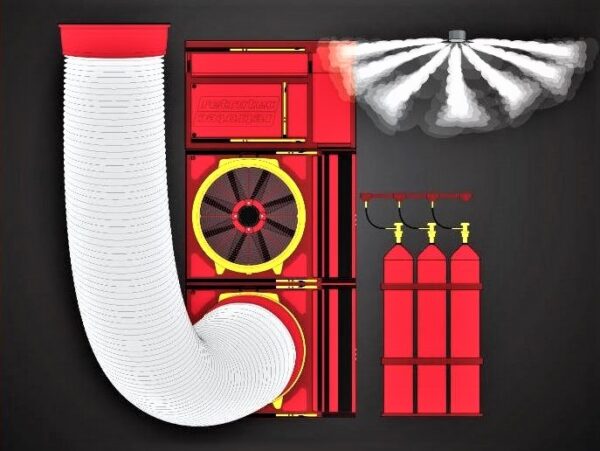

- The door fan equipment is set up in a suitable door opening. Personnel may continue to work within the enclosure during the test and may enter and leave, subject to access, except when pressure readings are being taken.

- Any air handling equipment involving supply into, or extract from, the enclosure will need to be set by the client or end-user into the same condition as would occur on system discharge (usually dampers closed and fans off). This need occur only whilst pressure readings are taken. Re-circulation and a/c units without fresh air make-up may be left operating throughout the test to prevent temperature build-up in the enclosure. Details of the arrangements are note.

- The extinguishing system and enclosure data obtained earlier is entered on to the computer. This calculates the design concentration and the column pressure (typically between 4 and 20Pa) that would be exerted by the gas after discharge

- The door fan(s) is used to pressurise and depressurise the enclosure to the column pressure and the fan pressure required in each case is recorded. For certain system design a series of pressure readings are taken.

- The pressure data is entered on to the computer which calculates the airflow, equivalent leakage area and the retention time.

If the result satisfies the specified retention time (usually 10 minutes) the enclosure is deemed to have passed the test. - If the retention time is less than that required, a detailed inspection is undertaken to establish the main leakage paths. This includes floor and ceiling voids as relevant.

- On occasions, chemical smoke pencils may be used in conjunction with the door fan equipment to assist leakage identification. These produce only very small quantities of smoke at the perimeter of the enclosure and are not used in the vicinity of any sensitive electronic equipment.

- Should the leakage path distribution be found to be other than the worst case situation assumed in the initial computer calculation, the retention time is recalculated accordingly. Also, if practicable, major leaks may be temporarily sealed, new pressure readings taken and a revised retention time calculated. Retention times meeting requirements are recorded as passes, subject to any necessary corrective actions; those not doing so are reported to have failed.

- A written test report will be submitted. The report contains details of the enclosure, extinguishing system parameters, pressurisation results and predicted retention time graph. Recommendations are given advising the sponsor of any leakage areas or other features requiring remedial action.

Note – The duration of the room integrity test is approximately two hours per enclosure.

We can help with your room integrity test requiments

We are a multi UKAS accredited company so you can be sure our reportage is of the highest quality. We undertake Room Integrity Testing on all types of protected enclosures from huge power station turbine enclosures, through to server rooms and data centres. We are now one of the leading Room Integrity Companies in the UK.

Our Engineers have over 40 years combined experience within the Fire Suppression Industry and are able to provide help and advice on your Room Integrity Test needs. We can also help if you have previously failed your integrity test, we can visit site and undertake localised smoke testing with air leakage reports. We can even undertake the fire sealing works if so required.

It is our ongoing aim to provide clients a ‘one stop’ Room Integrity Testing service to cater for their most exacting requirements. We only use high quality equipment that is UKAS calibrated – a basic requirement of a UKAS accredited testing laboratory.

For further information on our room integrity testing services, please contact our technical manager Darren on 07775623464; or email us at info@aptsoundtesting.co.uk