New residential developments in Reading require planning consent and dependant on the location of the development. This is a requirement under the National Planning Policy Framework in England and Wales. The approval of planning permission may require an acoustic assessment to evidence that suitable internal and external noise levels can be achieved over a 24 hour period. The main two reasons you are required to undertake a noise survey are:

a. The application is for proposed noise sensitive development, such as residential, next to existing sources such as major transport routes, industry or commercial uses.

b. The application is for a development that has the potential to cause noise disturbance to existing residential properties. For example, industry, or other development with fixed machinery/plant.

It is very important that the environmental protection team have the requires noise survey information at hand to assess if the proposed development is suitable for the area, and that adequate noise controls can be implemented.

The problem with submitting the noise survey later on in the process is that delays may be incurred to application process. It is often not possible to grant planning consent with a condition requiring a noise survey at a later date, as until a noise survey is completed the Environmental Protection Team cannot assess what the noise impact may be to the area of the development.

APT Sound Testing have undertaken hundreds of successful noise surveys for residential developments supporting planning consultants, architects, contractors and private individuals to ensure the most practical and cost effective acoustic solutions are implemented at the design stage. We work on projects of all sizes, from small single dwellings to large apartment blocks.

Acoustic design measures to control noise in Reading

Where possible, noise should be controlled at source; for example, the inclusion of noise barriers next to a busy road or the installation of an acoustic enclosure around a piece of industrial plant. The developer should also look at the design and layout of the proposed development to establish if changes will reduce the level of noise, i.e. residential accommodation designed with no windows facing a busy road or railway track or the inclusion of acoustic trickle vents.

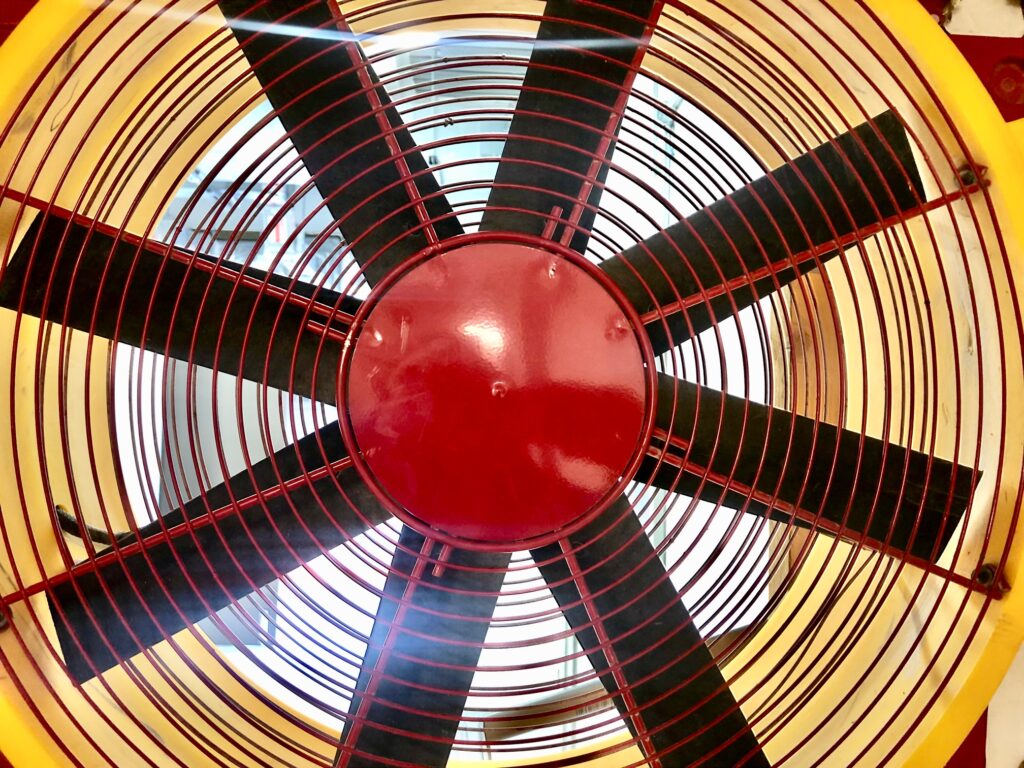

As a last resort, noise reduction measures such as acoustic glazing to habitable rooms may be acceptable. Any proposal to reduce noise either at source, by design and layout or by building treatments such as glazing should be supported by full information/calculations to indicate the likely level of noise; our Reading noise survey reports contain full noise predictions. Where plant is to be installed on a roof or wall then the acoustic output of the proposed plant should be assessed and spec’d accordingly.

The layout, orientation and screening of buildings should be considered before sound insulation design. Some of these design considerations are:

- Position and orientate the development to minimise noise disturbance, i.e. minimise windows on the elevation facing traffic.

- Where possible avoid placing bedrooms next to kitchens, living rooms or bathrooms in adjacent properties.

- Where possible avoid placing bedrooms next to stairwells, entrance halls or lift shafts

- Ideally no windows should face a busy road, railway or commercial activity. If this is not possible, only windows of non-habitable rooms such as kitchens and bathrooms should face a noise source.

It is worth noting that good acoustic design is not just required for external noise affecting a development, it is also needed to protect residents against unwanted noise transference between dwellings.

Under Part E of the Building Regulations, developers are required to ensure the separating walls and floors between adjoining dwellings achieves the minimum acoustic design standards. We can provide specialist design advice and testing to ensure you easily achieve and exceed the requirements of Approved Document E.

APT Sound Testing are UKAS accredited testing laboratory No. 4340 for sound testing, so we can provide pre-completion sound testing to sign off your development with Building Control. For more information on these services visit our ‘Sound Testing’ page.